Skilful, reliable and stable energy provider

We are responsible for significant assets, and we take good care of them. With timely investment and maintenance, we can ensure our position as a reliable energy supplier for our customers.

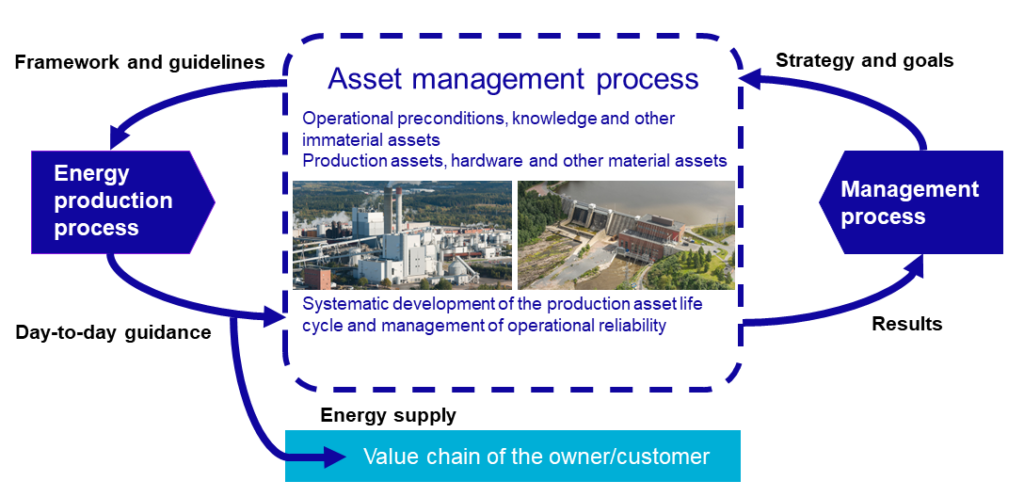

One of the three main themes of Pohjolan Voima’s strategy is “Top asset management expert”. It means safeguarding the value of all our assets and developing our competitiveness in the long term. In this work, we draw on the skills of our expert organisation and extensive network, as well as the opportunities offered by technology.

We actively monitor changes in the operating environment and technological advances, actively manage risks to develop our assets by optimising the lifecycle and cost-effectiveness of our energy production, and ensure the prerequisites for our production.

Asset management means continuous goal-oriented improvement

Asset management is a systematic long-term process of continuous improvement against set strategic objectives and key performance indicators. The key indicator in asset management is timely high availability, while ensuring cost-effectiveness and long-term lifecycle management. We therefore assess our asset management measures through audits, analyses and key performance indicators.

Well-managed production assets ensure reliable energy production for our customers. Furthermore, the value of production assets increases with investments and the development of production, which in turn is reflected as additional value generated for our customers – and it improves their competitiveness.

Network partnerships in maintenance

We work with a wide network of the best possible partners. We ensure the long-term capability of our partners through common objectives, contractual cooperation and competence development. With our partners, we develop asset management, seek synergies in power plant maintenance and share best practices.

We are also part of an HSEQ supplier assessment cluster: Pohjolan Voima relies on the strength of a cluster in occupational health and safety, quality, and energy efficiency observations.

Valmet is our long-term partner in the optimisation of the functionality and availability of our bio- and hydropower plants. We also collaborate in tackling climate change, reducing emissions, increasing the share of recycled fuels and moving away from peat.

Read more about cooperation in networks under Sustainability.

Taking good care of plants throughout their lifecycle

We take good care of our plants throughout their lifecycle.

We have 18 power plants and associated structures and facilities. We take good care of them throughout their lifecycle – because it’s important and makes sense. Long-term planning of the maintenance of power plants, risk management and choosing the right partners are the keys. Operationally, good asset management covers systematic and diligent operation, preventive maintenance and rapid responses to disruptions.

We are constantly developing the ability of our production equipment to meet the strategic objectives and respond to changes in the operating environment. We invest in making our operations and production processes even more flexible, secure and energy efficient.

In particular, we have invested in developing our production lifecycle with advanced automation, digitisation and proven state-of-the-art technology. Overall, we are guided by our sustainable lifecycle approach and our strategic objectives.

Also read about the digital path to the future of energy

Annual outages at thermal power plants are carried out in accordance with a systematic programme in different parts of the plants: fuel handling, the boiler, the turbine and the auxiliary equipment. The measures are based on inspections, analyses and equipment-specific lifecycle plans.

Annual outage reports are analysed for use when planning the next steps in ensuring reliable energy production.

Hydropower plants are regularly refurbished

Caverion is our partner in the preventive maintenance and the improvement of the availability of our hydropower plants. Their operation teams act as our eyes and ears at the power plants, supporting our own asset management experts.

Our hydropower plants are regularly overhauled in accordance with our overhaul programme.

In Tengeliönjoki river, the Portimokoski hydropower plant will undergo a major overhaul in the second half of 2026.

The most recently refurbished hydroplant is Haapakoski in the Iijoki river. The overhaul of it’s turbine was completed in January 2025. In the Kokemäenjoki river, the refurbishment of the turbines at the Melo hydropower plant began in late 2024.

Also in the Iijoki river, the Raasakka hydropower plant’s second generating unit was modernised by replacing the original stator by a new one in 2023.

The previous refurbished plant was Jumisko in Kemijärvi. The turbine dating back to the construction year was replaced, the generator was overhauled and the electricity and automation systems were modernised. In the latter task, completed in 2021, our partner was Insta Automation. The refurbishment increased the plant’s capacity by two megawatts.

In 2022, Finland’s first bored pile wall was built in an earth dam at the Melo hydropower plant in the Kokemäenjoki river in Nokia. The dam was reinforced with almost 200 bored piles, which were sunk into the bedrock to a depth of almost 70 metres. See a video on the reinforcement of the Melo earth dam (YouTube).

A well-managed production asset is also a significant environmental accomplishment. Read more about our sustainability measures.